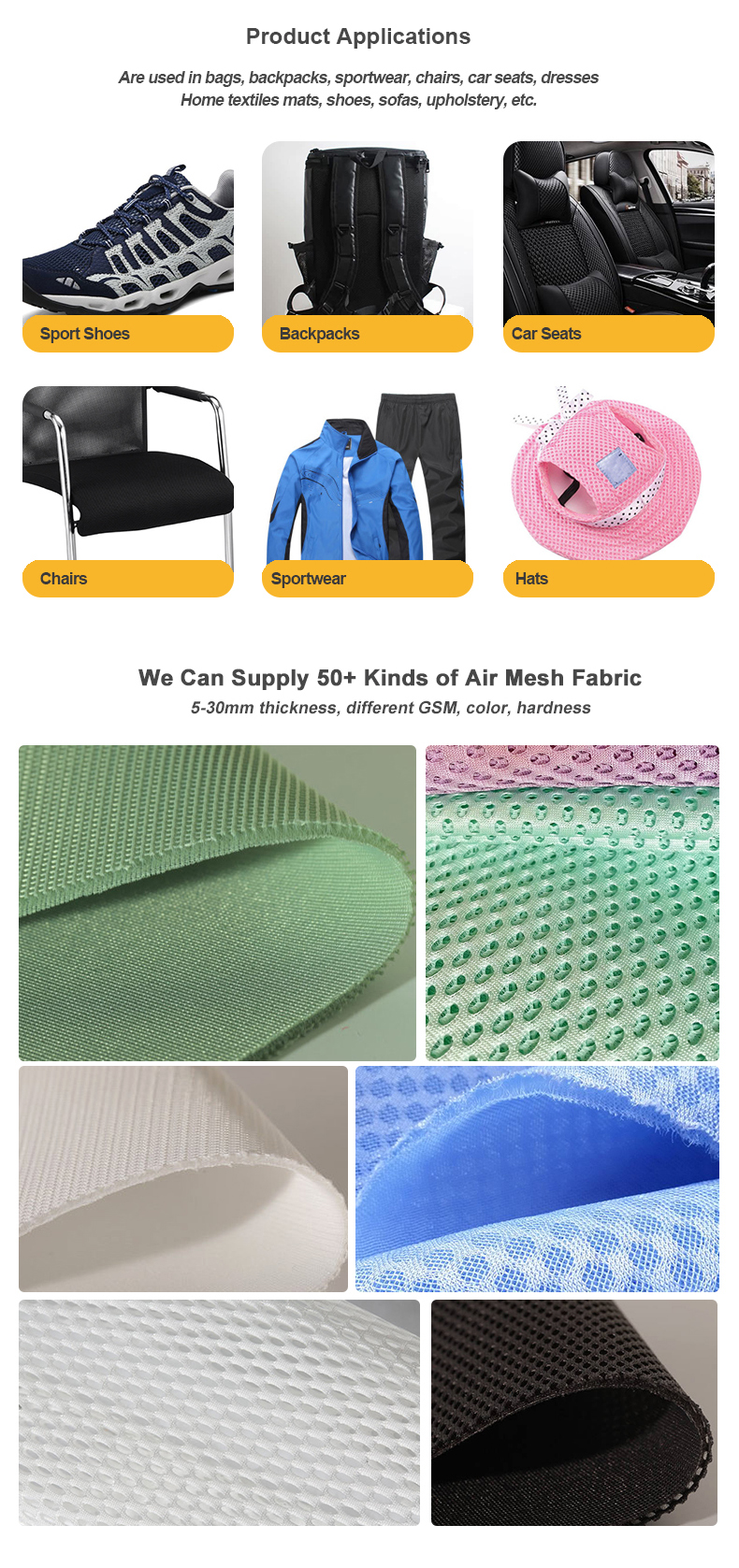

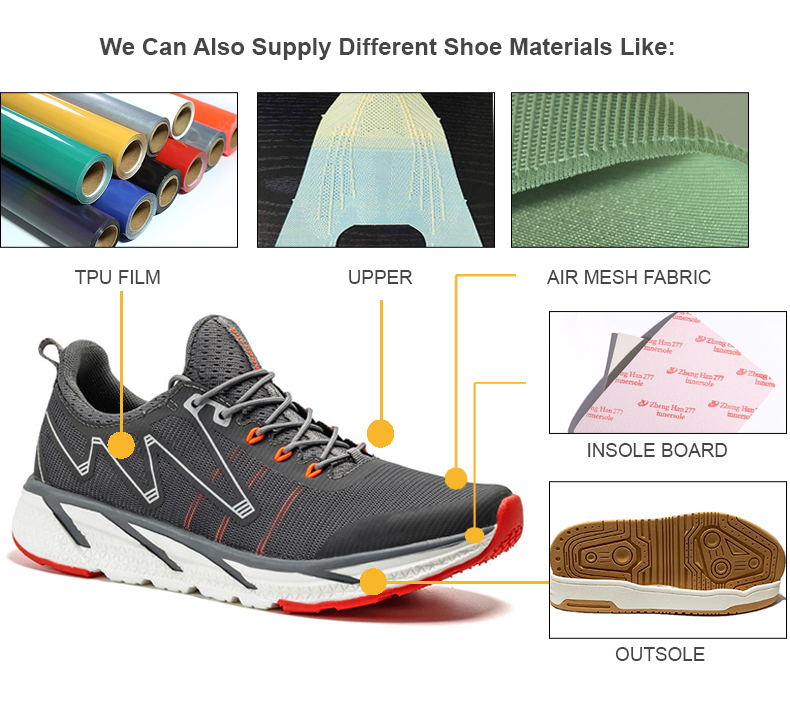

Polyester mesh stands out as a highly adaptable fabric used across various industries, including aerospace, automotive, marine, medical, and leisure. This guide highlights the key properties and applications of polyester mesh fabrics.

Composition and Structure

Polyester consists of synthetic polymer fibers created through a chemical reaction involving alcohols, carboxylic acids, and petroleum by-products. Manufacturers stretch and orient these fibers to form strong, water-repellent yarns that resist stains, UV degradation, and frequent use.

Key Features and Benefits

- Durability

First and foremost, polyester mesh fabrics showcase remarkable resilience. They resist damage from acidic and alkaline chemicals, corrosion, flame, heat, light, mold, mildew, and abrasion. This durability makes them suitable for demanding environments.

- Ease of Use

Additionally, polyester is widely available in textile manufacturing, which simplifies integration into products. When treated with lightweight resins, these fabrics become easy to sew and clean, significantly reducing maintenance time and labor.

- Hydrophobic Properties

Moreover, polyester mesh fabrics exhibit hydrophobic characteristics, effectively repelling water. This quality leads to excellent pigment absorption and quick drying times, making them ideal for outdoor and harsh environmental applications.

- Dimensional Stability

Finally, polyester fibers offer good elasticity, allowing the material to return to its original shape after stretching by 5-6%. This stability enables the design of high-stretch materials that maintain dimensional integrity.

In summary, polyester mesh combines durability, ease of use, water resistance, and stability. These qualities make it an excellent choice for a wide range of industrial and recreational applications.

评价

目前还没有评价